Designing parts for metal fabrication using SolidWorks 3D Solid Modeling has become our standard procedure for nearly every part, assembly, or product regardless of the quantity, size, or complexity.

The transition from drafting with a pencil to 2D drawings with AutoCAD to designing entire products with SolidWorks in 3D happened so gradually over the nearly 20 years we’ve been operating as a metal fab shop that I only recently stopped to think about how quickly we can go from idea to part design and prototype development today compared to even a few years ago.

There was a time when metal fabricators charged separately to design parts in two dimensions with AutoCAD. Then it became included as standard with part production orders. Enter 3D part design. At first, a design engineer needed weeks upon weeks of training to derive any value from the software. Metal fab shops had to charge a separate line item to recover some of the investment in design time and software costs with every three dimensional part.

But our engineering team has used SolidWorks on hundreds and hundreds of metal part designs for so many years that we just started including it as standard procedure with each part production run. Of course, we offer design engineering services separately, but designing metal parts in 3D has become so seamlessly integrated into our process that it seems senseless even to offer access to outdated technologies.

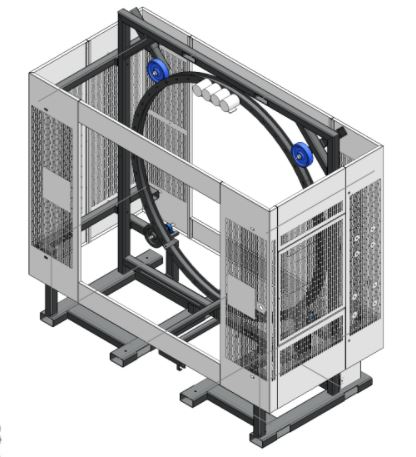

Once we design a part from scratch in 3D or convert a 2D CAD drawing into a 3D model (send us your PDF, DWG or DXF file!) it’s easy to visualize exactly how the finished part will look, fit, and perform within an assembly, and any changes can be made before incurring a cent of manufacturing time or material. In fact, our software automatically generates the programming for the CNC machining, laser cutting, or our other in-house processes. This precise communication among computers eliminates the potential for operator error. Every part gets cut and fabricated correctly on the first try without wasting any precious time or materials.

I still enjoy the idea of designing fabricated metal parts with a pencil and paper. But to fabricate these metal parts fast, on-spec, and at the lowest cost possible every time, I’ll use our 3D SolidWorks modeling package every time.

Contact us to learn more about our design engineering services.