Even stationary materials can create unexpected hazards in a busy manufacturing environment. That was the case at dormakaba USA Inc., a leader in access and security solutions. At its Reamstown, Pennsylvania, facility, the company found a smarter, safer way to manage aluminum extrusions thanks to a collaboration with TAB Industries.

The Problem: Workplace Injuries

For Kyle Demore, Entrance Systems (ENS) Production Manager of dormakaba’s Entrance Systems division, safety had become a growing concern. The facility’s aluminum extrusions were being stored flat on carts, often extending past the edges. This posed a significant risk.

“We were running into safety concerns with the overhang of the material off the cart,” Demore explains. “It presents itself right at eye level but sometimes blends in with the background, so it’s very easy to bump your head.”

The injuries weren’t isolated. Workers suffered scrapes to their ankles, and in one severe case, a trip over low-stored material resulted in a broken rib. With over 140 employees and production demands rising—especially after a new retail client tripled output—Demore knew the solution needed to do more than address safety: it had to optimize space and workflow.

The Solution: Custom Vertical Storage Carts

To address the challenge of improving safety and maximizing floor space, dormakaba turned to TAB Industries.

Dormakaba and TAB Industries had an existing relationship, and when the opportunity arose to request quotes, TAB came out ahead.

“They won the bid as far as lead time, quality, and costs are concerned,” Demore said.

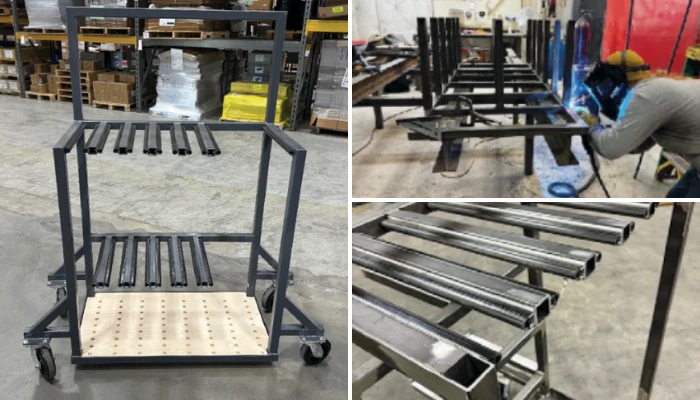

Working closely with Demore, we custom-engineered carts to store extrusions vertically rather than horizontally, which significantly reduced the cart footprint and eliminated those dangerous overhangs. Key features of the new carts include:

- Uniform spacing to ensure each extrusion fits securely

- Rubber bumpers to prevent scratching or material damage

- Perpendicular positioning for dormkaba’s materials, allowing extrusions to be loaded safely and efficiently without stacking or crowding

The carts were built to precise specifications and reviewed over multiple design sessions to ensure ergonomics and user satisfaction. The result? A cart that performs just as well as it protects.

Safety & Efficiency with the TAB Wrapper Tornado

Beyond the material carts, dormakaba is also exploring the TAB Wrapper Tornado, our signature orbital stretch wrapper, as part of a cost-saving initiative to improve shipping and reduce material waste.

The wrapper automates the pallet-wrapping process, allowing a forklift operator to wrap loads without leaving the cab. Compared to manual banding, it’s a faster, safer solution that reduces the risk of lacerations and repetitive strain injuries.

A Partnership for Growth

With production at the Reamstown facility on the rise, dormakaba needed a smarter way to work. Partnering with TAB delivered just that: a safer work environment, more efficient floor space usage, and the flexibility to scale as demand grows.

“We will continue to partner with TAB Industries,” Demore affirms.

Whether it’s custom carts or cutting-edge wrapping equipment, TAB Industries proves that manufacturing innovation doesn’t have to come at the expense of safety, quality, or cost.

Reach out to us today to find out how we can help you streamline your operation.