Buying a laser cutter and offering custom laser cutting services was a natural progression after many, many years of experience in metal fabrication, welding, assembly, and other metals manufacturing services. We already had the industry knowledge and metalworking expertise in-house. We know where we excel. We’d designed and manufactured thousands of parts and products with laser cutting, waterjet cutting, plasma cutting, and other metal cutting methods. It was clear that for the vast majority of metal parts that need to be cut for OEM manufacturers, laser cutting would be the ideal process – clean, fast, high quality cuts. The few parts that truly do need precision waterjet cutting are well served by existing waterjet cutting companies and we didn’t want to add the dirty wastewater infrastructure or the liability of environmental contamination.

We also found it easy to commit to buying laser cutting machines because we were spending huge amounts of money buying laser cut metal parts from nearby laser cutting companies in Pennsylvania to build our TAB Wrapper Tornado line of orbital wrappers. Each wrapping machine needs more than 40 different laser cut parts. Spending $250,000.00 a year every year into the foreseeable future for these parts made the one-time cost of owning our own laser cutting equipment seem very reasonable.

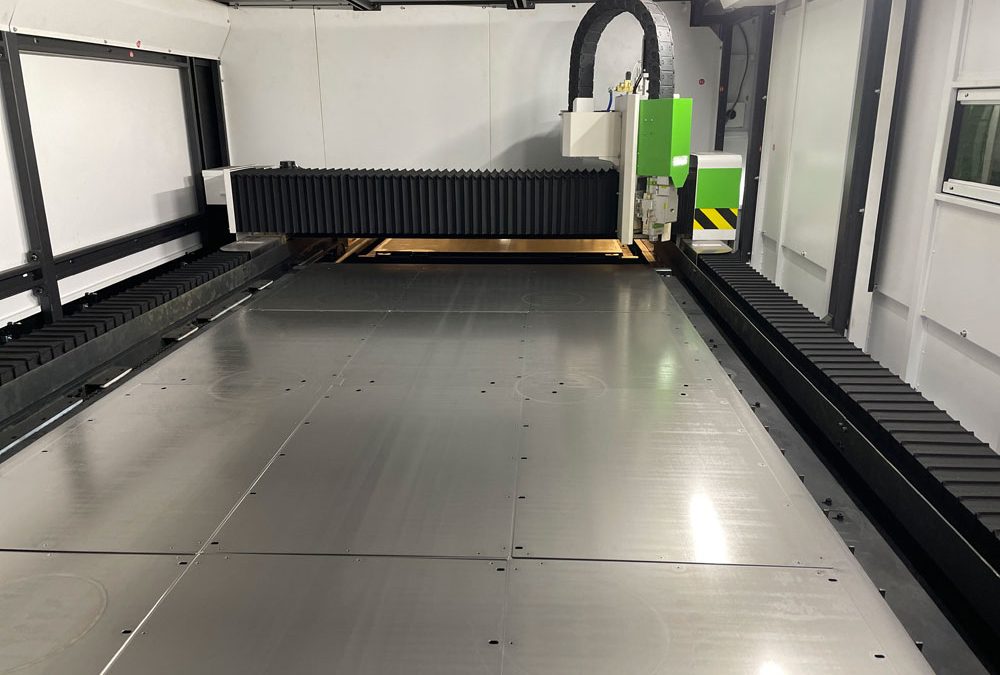

Now with our 3300 Bescutter Fiber Optic Laser cutting system, and our FLY3015 Bescutter Fiber Laser cutting system, we’re producing high quality metal parts incredibly fast and keeping our costs and lead times under control. We’re delivering the TAB Wrapper Tornado pallet wrapping machines about two weeks faster than last year. For us, the key is control. We wanted to offer laser cutting to our existing customers with the very fast lead times and the same dependable schedules they’re used to getting with our other services. And that means we had to setup our laser cutting shop in-house.

Of course, once word got out that we’d expanded our in-house services to include laser cutting, the phones lit up – so to speak. We’ve had to add a shift and now we’re looking at buying yet another laser cutting system.

For a laser cutting quote, click here.